Bitumen

WHAT IS BITUMEN?

Bitumen is a black or dark-colored (solid, semi-solid, viscous), amorphous, cementitious material that can be found in different forms, such us rock asphalt, natural bitumen, tar and bitumen derived from oil, which is referred to as petroleum bitumen. Currently most of the roads globally are paved with bitumen. Today the world’s demand for bitumen accounts for more than 100 million tons per year which is approximately 700 million barrels of bitumen consumed annually.

Bitumen is a viscous substance that exists in a liquid to a semi-solid phase. It has a blackish-brown color.

It is generally composed of asphaltene resin and other petroleum compounds.

Different compositions of bitumen result in different properties.

Bitumen

BITUMEN APPLICATION

Known for its adhesive and cohesive assets, bitumen is mostly utilised in the construction industry. Bitumen is applied on road paving because it is viscous when hot, but solid once it cools down. Therefore Bitumen operates as the binder/glue for pieces of the aggregate.

We are well aware of the complexity of bitumen as a product and an in-depth knowledge and detailed understanding of the way the roads are built is crucial. Specialists in bitumen recognize bitumen as an advanced and intricate construction material, not as a mere by-product of the oil refining process.

The ultimate paving material (also referred to hot mix asphalt concrete – HMAC or HMA) consists of about 93 – 97% mineral aggregate (stone), sand and filler. The remaining percentage is bitumen.

Bitumen is applied in construction and maintenance of:

• Reservoir and pool linings

• Sound proofing

• Pipe coatings

• Cable coatings

• Paints

• Building Water Proofing

• Highways

• Airport runways

• Damp proofing

• Car parks

• Racetracks

• Tennis courts

• Roofing

• Dams

• Tile underlying waterproofing

• Newspaper Ink Production

• Footways / Pedestrian Way

More than 85% of the world’s bitumen production is used for road construction, 10% is used in other constructions and 5% is used in a variety of other industries, including insulation.

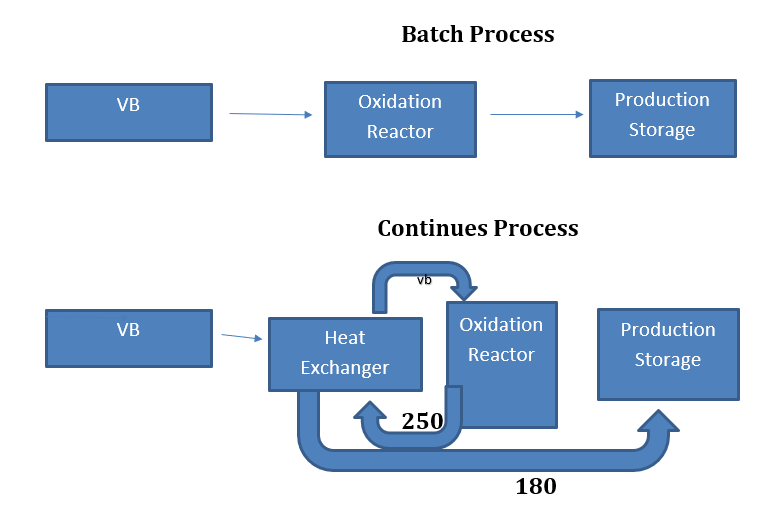

HOW BITUMEN IS PRODUCED?

(THE PRODUCTION PROCESS OF BITUMEN)

Petroleum Bitumen, normally called “Bitumen” or “Asphalt” is produced by refining crude oil. Used as a binder in road-building products, it is a very viscous, black or dark brown material.

The crude oil is pumped from storage tanks, where it is kept at about 60°C, through a heat exchanger system where its temperature is increased to typically 200°C by exchanging heat gained from the cooling of newly produced products in the refining process. The crude is further heated in a furnace to typically 300° C where it is partly vaporized into an atmospheric distillation column. Here the physical separation of the components occurs. The lighter components rise to the top and the heavier components (the atmospheric residue) fall to the bottom of the column and pass through a second heat exchanger prior to treatment in a vacuum distillation column. Finally, Bitumen is obtained by vacuum distillation or vacuum flashing of atmospheric residue from the vacuum distillation column. This is “straight run bitumen”. This process is called bitumen production by straight run vacuum distillation.

An alternative method of bitumen production is by precipitation from residual fractions by propane or butane-solvent deasphalting. The bitumen thus obtained, has properties which are derived from the type of crude oil processed and the mode of operation whether it is in the vacuum unit or in the solvent deasphalting unit. The grade of the bitumen depends on the amount of volatile material that remains in the product: the smaller the amount of volatiles, the harder the residual bitumen.

1- Bitumen of Natural Origin

Million years ago, living organisms such as microscopic algae (diatoms) were buried under sedimentary rocks, in swamps, and in other aquatic habitats.

These residues were converted to natural bitumen under the pressure of the upper sedimentary layers and temperatures above 50 °C.

Bitumen is now found in hills and oil lakes. Most of the bitumen resources are in Canada, Venezuela, and Oman. There are also natural bitumen mines in the west of Iran. It has different ash content.

Natural bitumen or Gilsonite has many impurities including sulfur and heavy metals. The cost of extracting and using this bitumen is higher than the bitumen obtained from crude oil.

It is usually used as an additive for waterproofing coating, mud drilling, and road construction.

2. Crude Oil Distillation

Crude oil is the primary source of bitumen for the industry. Crude oil is a mixture of different compounds that is separated by a distillation tower. The remnants of the distillation tower, called vacuum bottom, are transferred to be processed and turned into bitumen.

Different types of bitumen, including penetration bitumen or oxidized bitumen, are produced by a different process on vacuum bottom in the refinery. The main application of this bitumen is in road construction.

Read the different types of bitumen used in road construction to know more details.

To become familiar with the way bitumen is created in nature, how it is extracted from oil, what its classifications are, and what uses it has, watch the below video:

What is the Difference Between Bitumen, Tar, and Asphalt?

In the United States, the words bitumen and asphalt are synonymous, but in general, asphalt means the composition of aggregates and bitumen, as a binder, that is used for road construction.

Bitumen is a hydrocarbon substance. It is found naturally or comes through refining processes from crude oil.

Tar is also a dark hydrocarbon material. But the difference between tar and bitumen is in the origin of their production. The tar is obtained through a special distillation process from wood or coal. Coal-based tar is high in benzene, which is cancer-causing.

Tar is mostly used in road construction. The tar wood has been used for thousands of years in northern Europe to waterproof boats, among other uses. Coal fiber and wood also have medicinal properties and are used to treat psoriasis and eradicate germs.

Read our article about “The difference between bitumen, tar, and asphalt”.

Types of Bitumen and Their Applications

Everything about Bitumen

Since various kinds of crude oils give various types of bitumen with completely different properties, grading bitumen is vital.

For grading bitumen based on its properties, refineries use a number of standard tests to measure the viscosity level, penetration value, performance, and consistency of bitumen.

The result of these tests is bitumen penetration grades and viscosity grades.

Other grades of bitumen, including cutback bitumen, oxidized bitumen, and bitumen emulsions are classified based on their production process.

1- Gilsonite (Natural Bitumen)

Gilsonite is natural bitumen with a shiny and smooth and solid appearance. Types of Gilsonite are classified based on their ash contents and the solubility in organic solvents.

Since it is a hard and brittle material, it is mostly used in powder form. Gilsonite composition is close to refinery bitumen.

Sometimes in the road construction industry, the combination of gilsonite with refined bitumen is used. Although it has a higher resistance to water penetration its degree of penetration and deformation is low.

Applications of Gilsonite

1. Printing industries

2. Painting industry

3. Drilling mud and cement

4. Asphalt and road construction

5. Casting sand additive

6. Chemical products

7. Improving the quality of bitumen

Micronized Powder of Gilsonite, Natural Bitumen

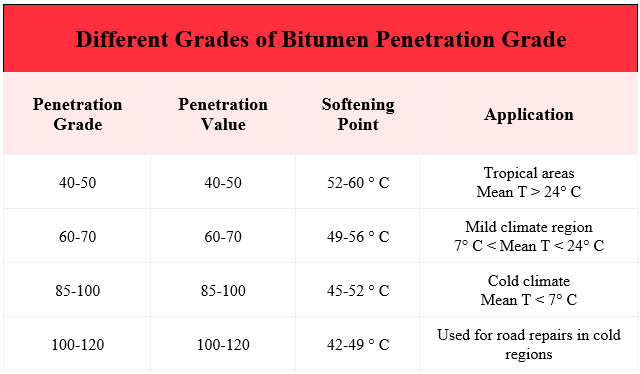

2- Penetration Grade Bitumen

Penetration bitumen is the most widely used bitumen for road construction.

After production in the refinery, it is classified by bitumen penetration test using a penetrometer apparatus. The deeper the needle penetrates into the bitumen surface, the softer it will be and suitable for colder weather. The most widely used bitumen for road construction is penetration bitumen of 60/70 grade and then grade of 80/100. Furthermore, 60/70 grade is widely used as a waterproofing material in buildings.

To use this bitumen, you should pay attention to the average temperature of the area and the amount of traffic.

In the table below, you can see the different grades of this penetrating bitumen along with its application.

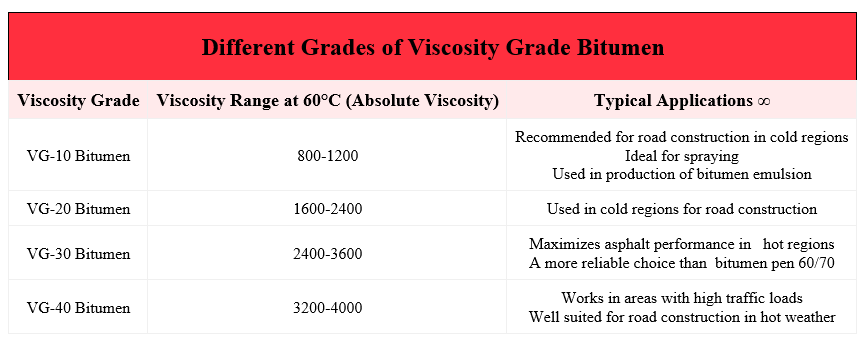

3- Viscosity Grade Bitumen

Viscosity grade bitumen is classified based on its viscosity after production of the bitumen in the refinery. This classification is almost newer than penetration classification. The highest consumption of this bitumen is in India.

Viscosity bitumen has four different grades that are VG 10, VG20, VG30, and VG 40. They have different applications.

The reason for using viscosity grading instead of penetration is the change in viscosity of bitumen at high temperatures.

Here are some advantages of VG bitumen to Pen grades:

• This grading system is designed to increase the accuracy of bitumen in hot temperatures. A specific grade of pen bitumen may show various results at a specific temperature, but VG bitumen behaves always the same.

• When there is a need to predict bitumen behavior in the hottest time of the year as well as its properties in normal weather conditions, VG bitumen is a better choice. Since viscosity testing is based on experimenting with bitumen’s properties at three different temperatures (25° C, 60° C, and 135° C), all grades of VG bitumen come with an easier application.